ProjectCommon Sands

Common Sands is an ongoing exploration of the extraction, transformation, application and end-of-life of sand and sand-based products. The project forms the basis for a number of multidisciplinary collaborations – offering alternative visions of value and responsibility through design.

Exhibition Geo Design Junk

Exhibition Geo Design Junk

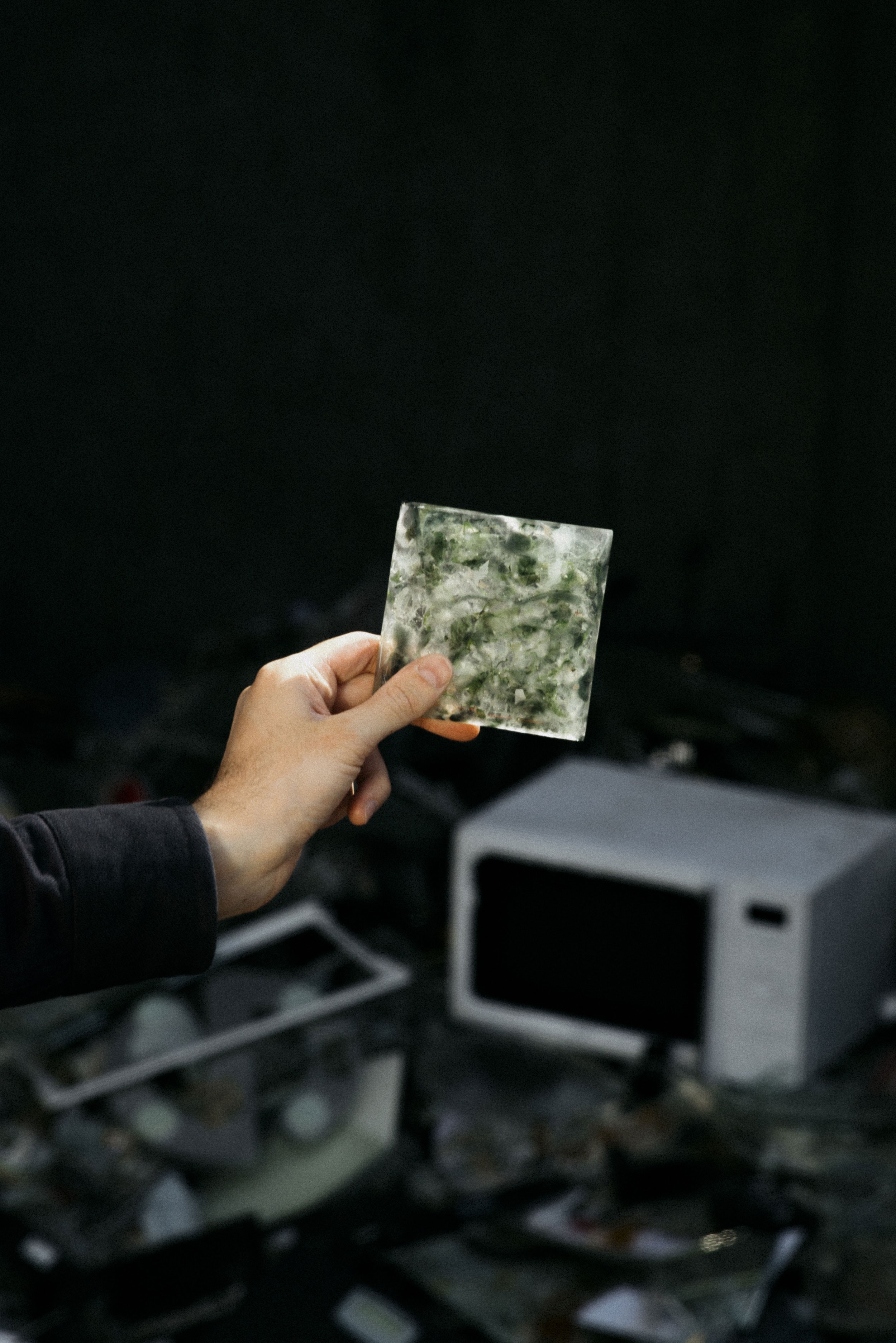

The microwave oven is the protagonist in this chapter of the Common Sands project for the exhibition GEO–DESIGN: Junk. All That Is Solid Melts into Trash, commissioned by Design Academy Eindhoven.

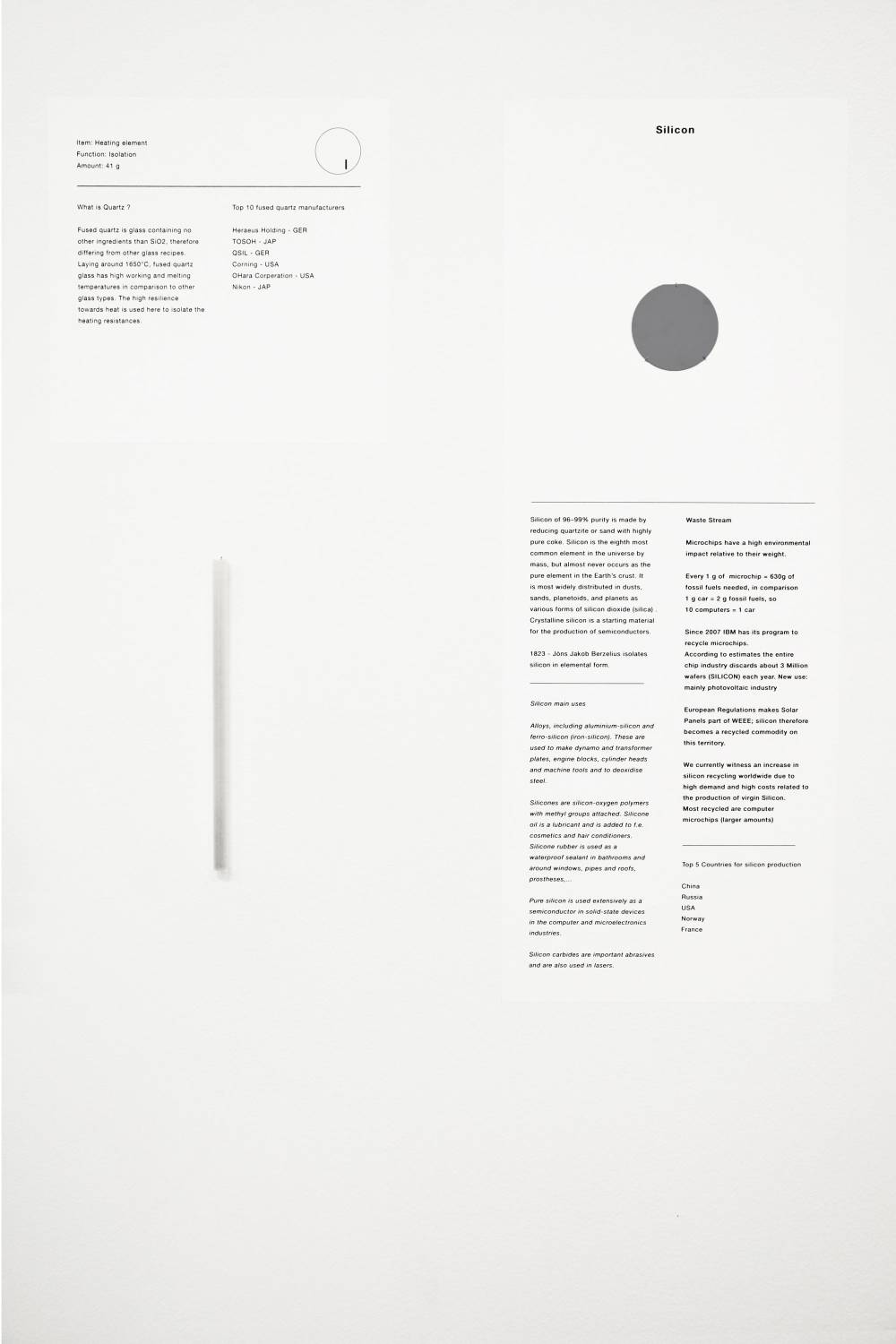

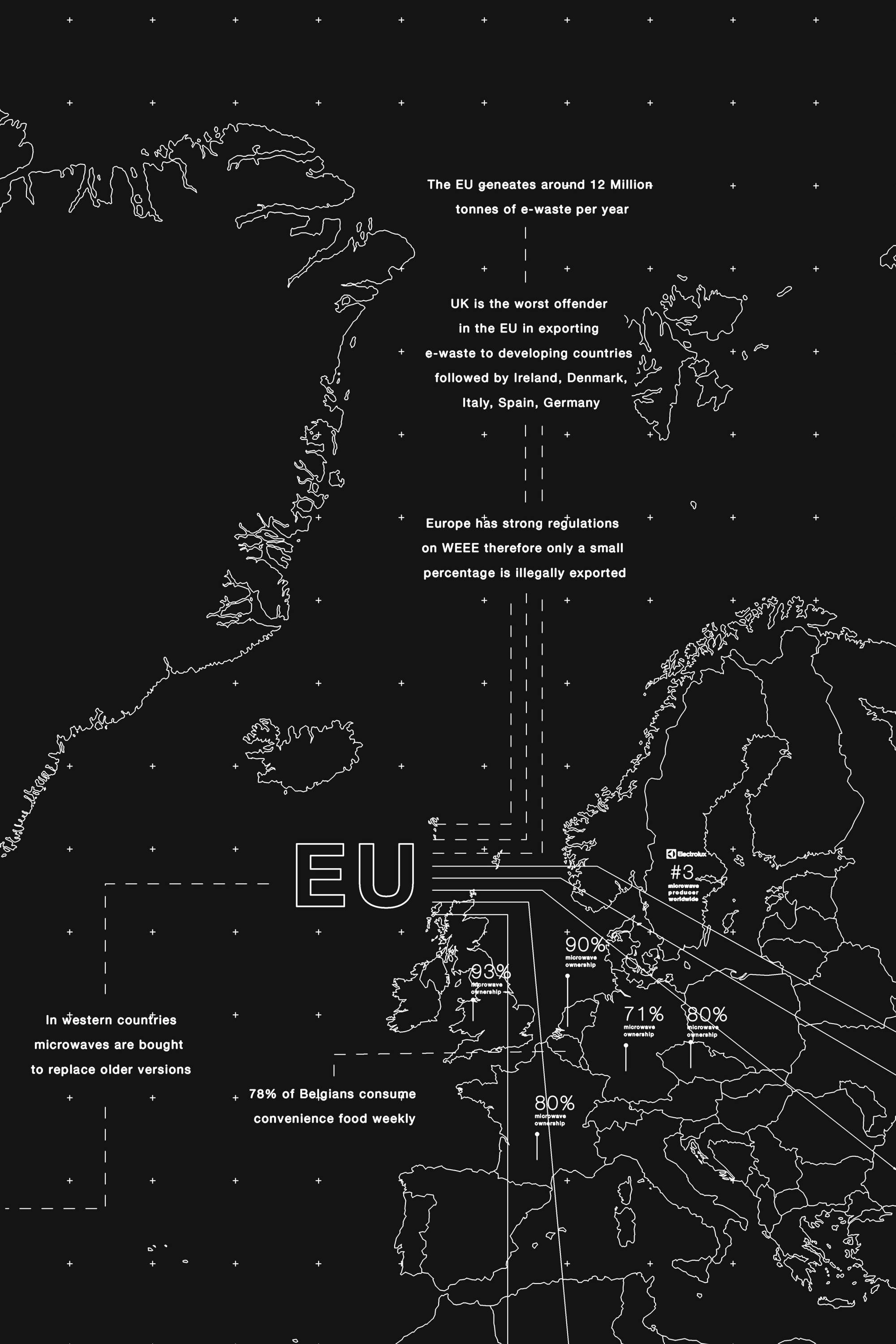

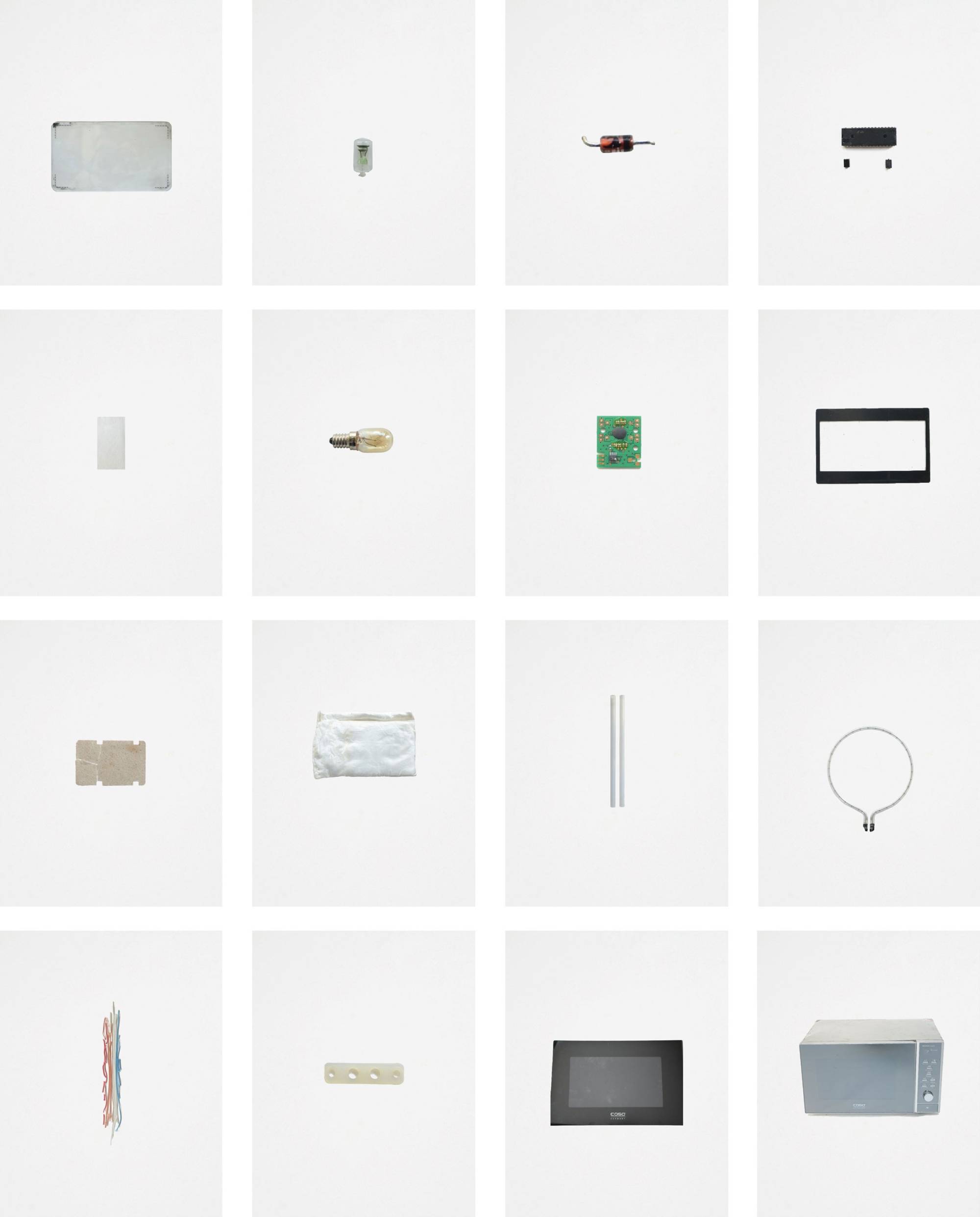

The microwave oven is a technologically advanced appliance used all over the world to warm or cook food. In this exhibition this icon of consumer electronics becomes a starting point to investigate the international production and disposal of silicate junk. Silicates are created from natural silica sand – a resource that stands under increasing amounts of pressure – and include glass, glass fibre, silicon and a range of other materials that are difficult for the layperson to identify. They are a fundamental material in the design of most electronic devices, making them an essential pillar of contemporary culture. Understanding the conditions that affect fabrication and scrapping is key to understanding how our culture is using the world’s resources, but manufacturers alienate us from this reality, either purposefully or unconsciously.

Van Abbe Museum, Eindhoven,

NL, 2019

Using the rich, global tradition of sand drawing, the exhibition reveals the life cycle of the microwave and its silicate components. Sand drawings have been found in many countries throughout history. They link East and West, North and South, echoing the assembly, use, dismantling and trashing of the microwave.

Sandpainting is the art of pouring coloured sands, and powdered pigments from minerals or crystals, or pigments from other natural or synthetic sources onto a surface to make a fixed, or unfixed sand painting. Unfixed sand paintings have a long established cultural history in numerous social groupings around the globe, and are often temporary, ritual paintings prepare for religious or healing ceremonies.

Sand Drawing,

Van Abbe Museum, Eindhoven,

NL, 2019

Van Abbe Museum, Eindhoven,

NL, 2019

Here, sand drawing offers a meditation on the processing of natural silica into jewels of sand technology before its final transformation into junk. The global influences on and impacts of microwave production and disposal are mapped as an orbital layer around the core narrative, revealing a matrix of regulations, materials and changing cultural and social mores and habits.

Cultural references of the microwave,

Van Abbe Museum, Eindhoven,

NL, 2019

Forite Tiles

Forite Tiles

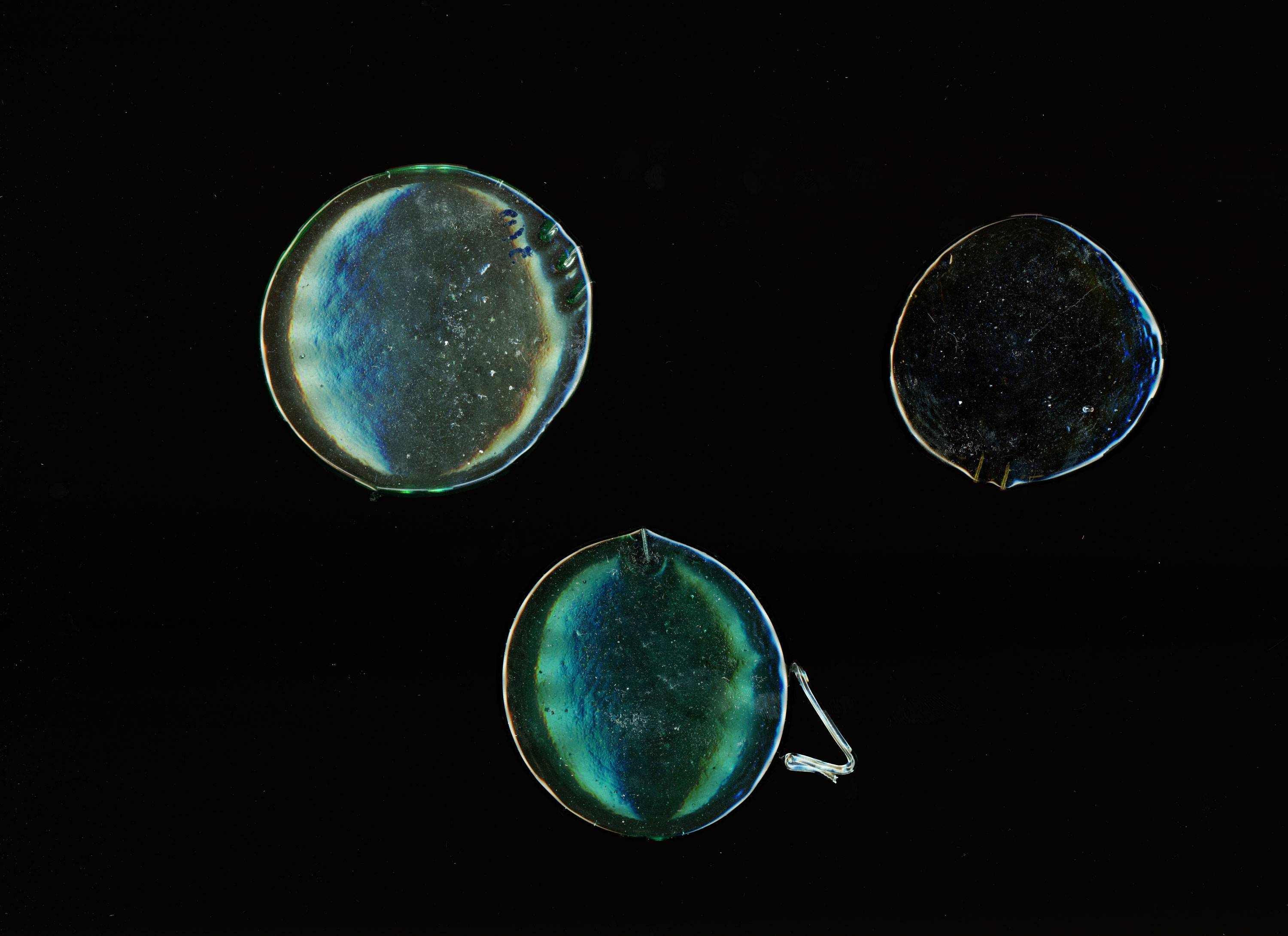

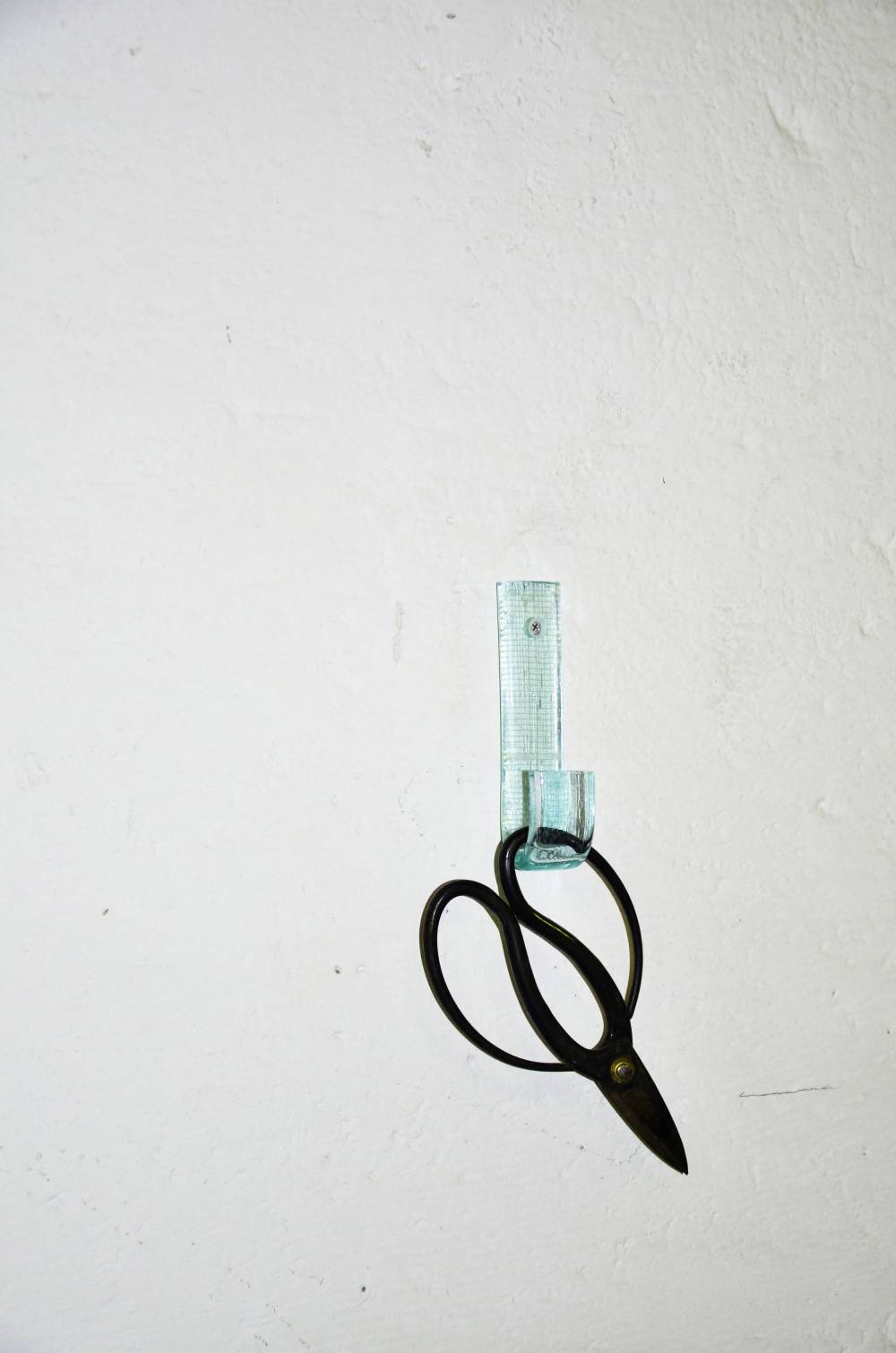

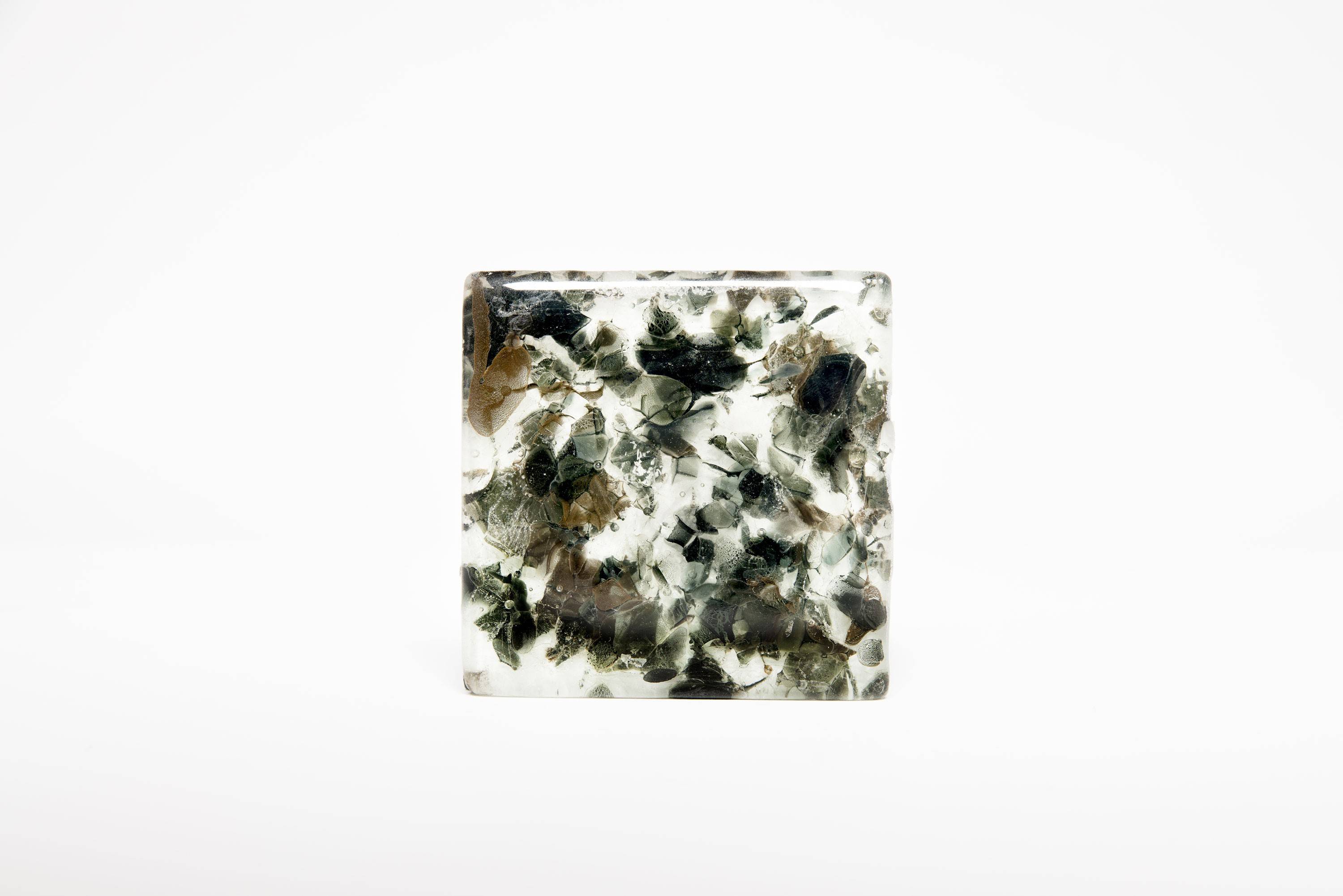

Common Sands–Forite Tiles is a collection of glass tiles made of repurposed glass components from discarded ovens and microwave ovens. The tiles are developed and designed by Studio Plastique in collaboration with Snøhetta and Fornace Brioni as the result of more than 3 years of research and experimentation. With the aim of creating sustainable, smart and refined architectural products, the project creates new value for an abundant yet unexploited group of materials.

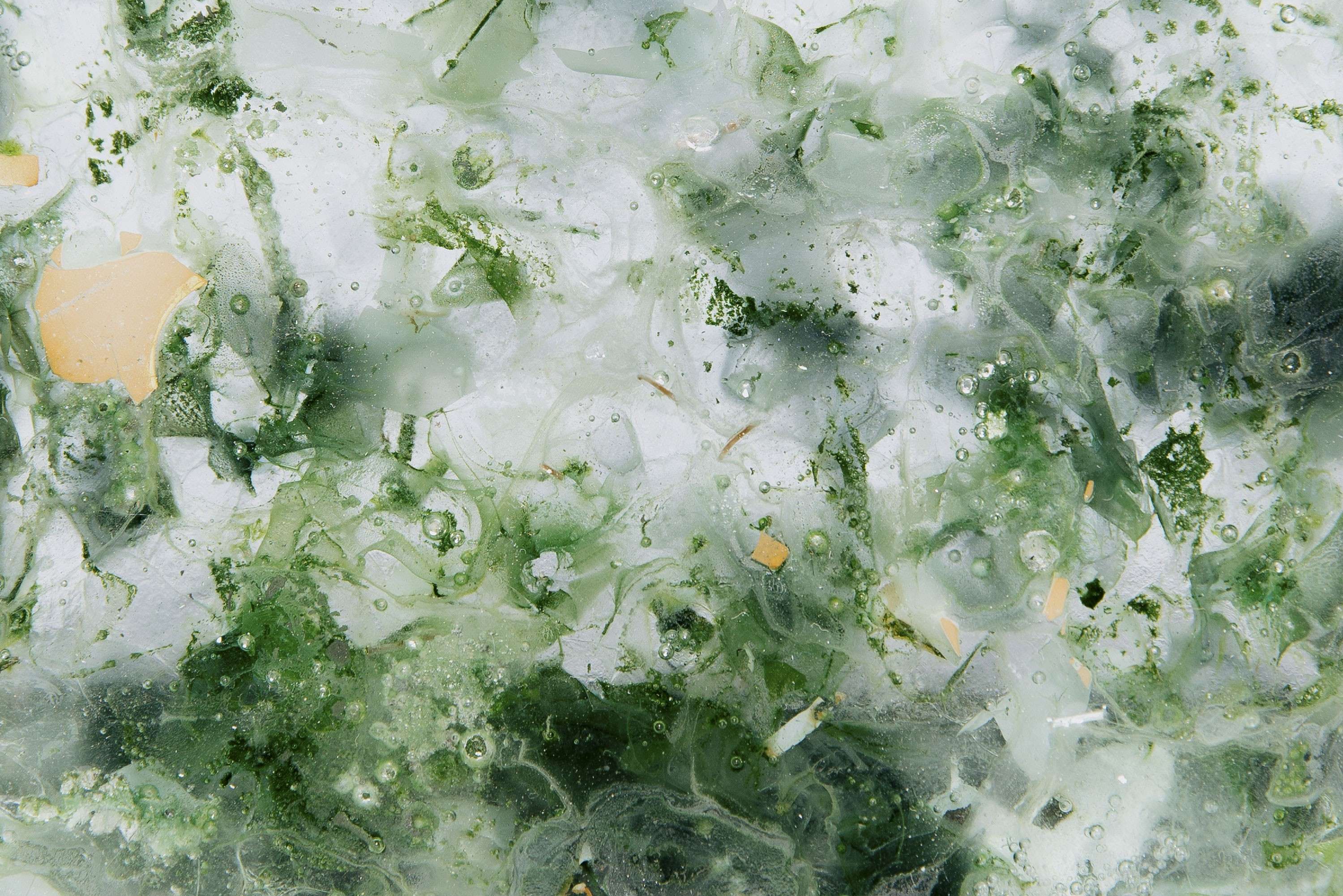

A prototype project for the new application of E-Waste glass, Common Sands-Forite Tiles positively leverages the unique properties of composition, colour, and structure inherent in the waste material into a series of architectural glass tiles. Ironically, it is these qualities which make the material un-recyclable in the first place! In an industry which demands transparency and consistency as a standard, Forite embraces the variance and complexity already embedded in the recycled materials. A focus has been set on waste glass from ovens and microwaves to demonstrate the aesthetic depth, function and potential of the material, without limiting the project to this stream alone.

Tiles have a long and pertinent tradition in architecture; covering roofs, floors and walls, creating functional, hygienic, and decorative surfaces. Additionally, the partial translucency of the Forite glass tiles makes them applicable to semi-transparent exterior walls and divisions for interior spaces. Spaces conceived with Forite tiles do not just look beautiful, they allow for naturally authentic environments whilst contributing to the reuse of otherwise wasted resources.

More pragmatically, tiles are the ideal production system in which this material finds a new use. The technical requirements for the production of glass tiles are compatible with existing protocols for ceramic tile production, seamlessly facilitating both production and implementation.

This project is a strong example of what can be achieved in terms of real, game changing, circular and sustainable design. Working across disciplines and specialisations, the collaboration between Studio Plastique, Snøhetta and Fornace Brioni meets contemporary challenges with ambitious, pragmatic and scalable solutions.

Homeware

Homeware

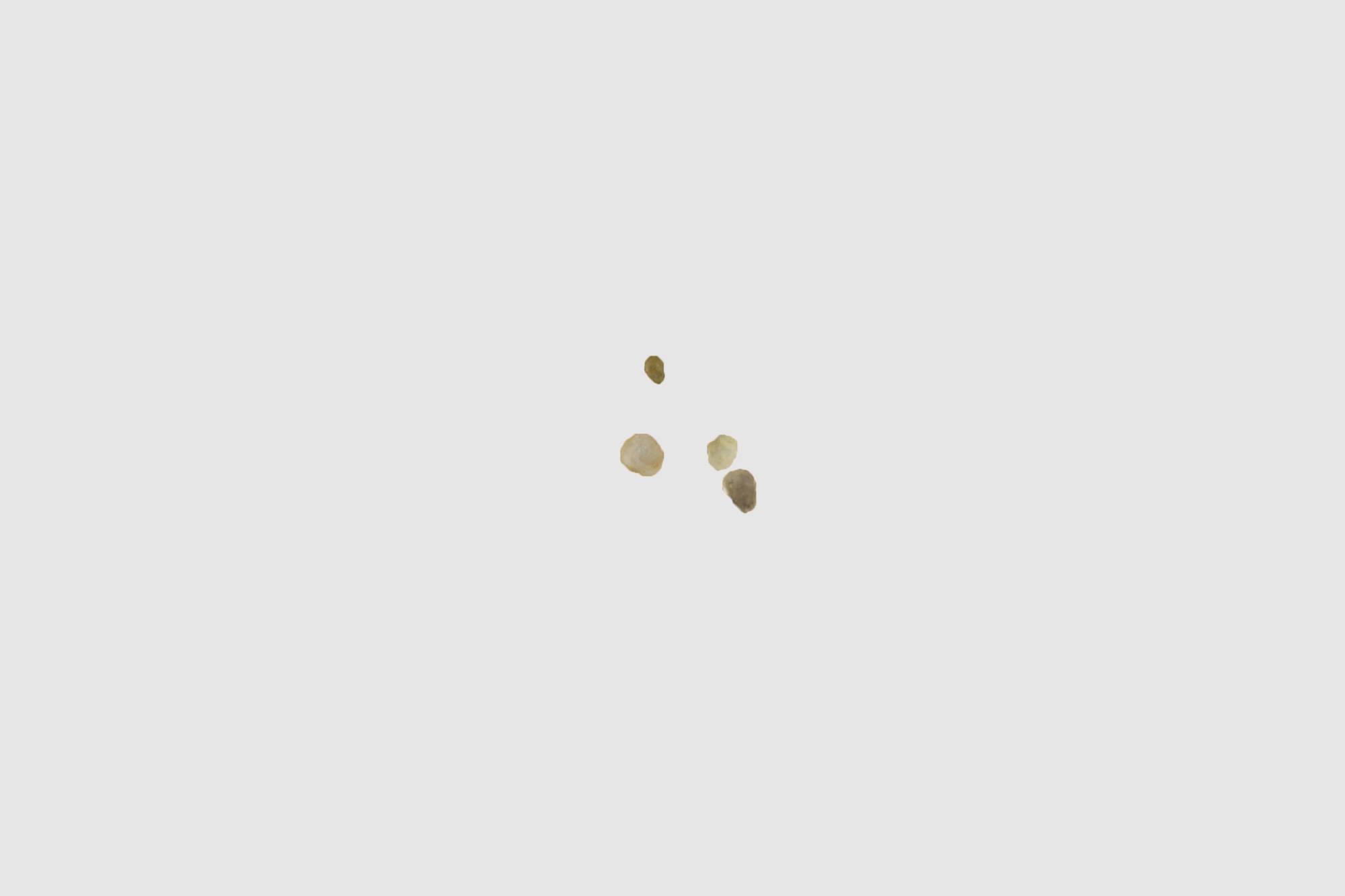

Common Sands-homeware is a collection of decorative and functional homeware products made from waste-glass components of discarded household appliances.

Currently the re-use of waste-glass from electric and electronic equipment (WEEE) is challenging the usual recycling processes. The inconsistent properties render this glass undesirable for a glass industry aiming for consistent results. The varying properties are due to a range of features inherent of the components and their applications, such as metal oxide coatings on the glass, coloured glass and varying glass compositions. These properties are used as an added value in the design and production of the objects as the project aims to explore the unique qualities of this unexploited resource. The objects are marked by laser to indicate origin, location and date of transformation of the resource in order to establish an informed relationship between resource, producer and user.

Common Sands-Homeware is the result of an intensive collaboration with experts and craftsmen, leading to the development of new methods and ultimately new perspectives for those local resources of global heritage.

Process

Process

The Common Sands project attempts to offer alternative visions of value and responsibility through design.

In terms of importance to our civilisation, one resource tops almost everything: Sand. This might be surprising to some, as sand is commonly seen as rather banal – something to lie on at the beach, or as part of a children’s playground. On the contrary, sand is integral to the continued functioning of our technology-driven society. Sand makes our electronic devices function, our homes light and warm, our communication fast (and ever faster) and our energy consumption more sustainable. We might even go as far as to term our current period “the Sand Age”.

In order for sand to become glass, microchips, solar cells, aerogel, insulation, or any number of other products, we enter a world of sophisticated technological production that simply defies belief. However, after all the effort made to extract, transport, refine and process sand into the most complex electronic components, almost nothing is done to recycle glass, silicon, silicones, microchips or glass ceramics when they reach the end of their lives. They simply land in the dump.

Existing EU recycling regulations work well for metals, less well for plastics and not so well for the sand-based materials integrated into our electronic appliances. Sand is too cheap, too abundant, and too difficult to recycle. However, this understanding stands in stark contrast to the geopolitical context of carbon-heavy sand mining, which is marked by both material scarcity and ecological disaster.

Far from being unlimited – sand is running out.

” Sand, rarer than one thinks [ … ] Sand [ … ] mined world-wide and account for the largest volume of solid material extracted globally. Formed by erosive processes over thousands of years, they are now being extracted at a rate far greater than their renewal. [ … ] The demand for aggregates stems from a wide range of sectors, including production of glass ” UNEP Global Environmental Alert Service (GEAS), 2014

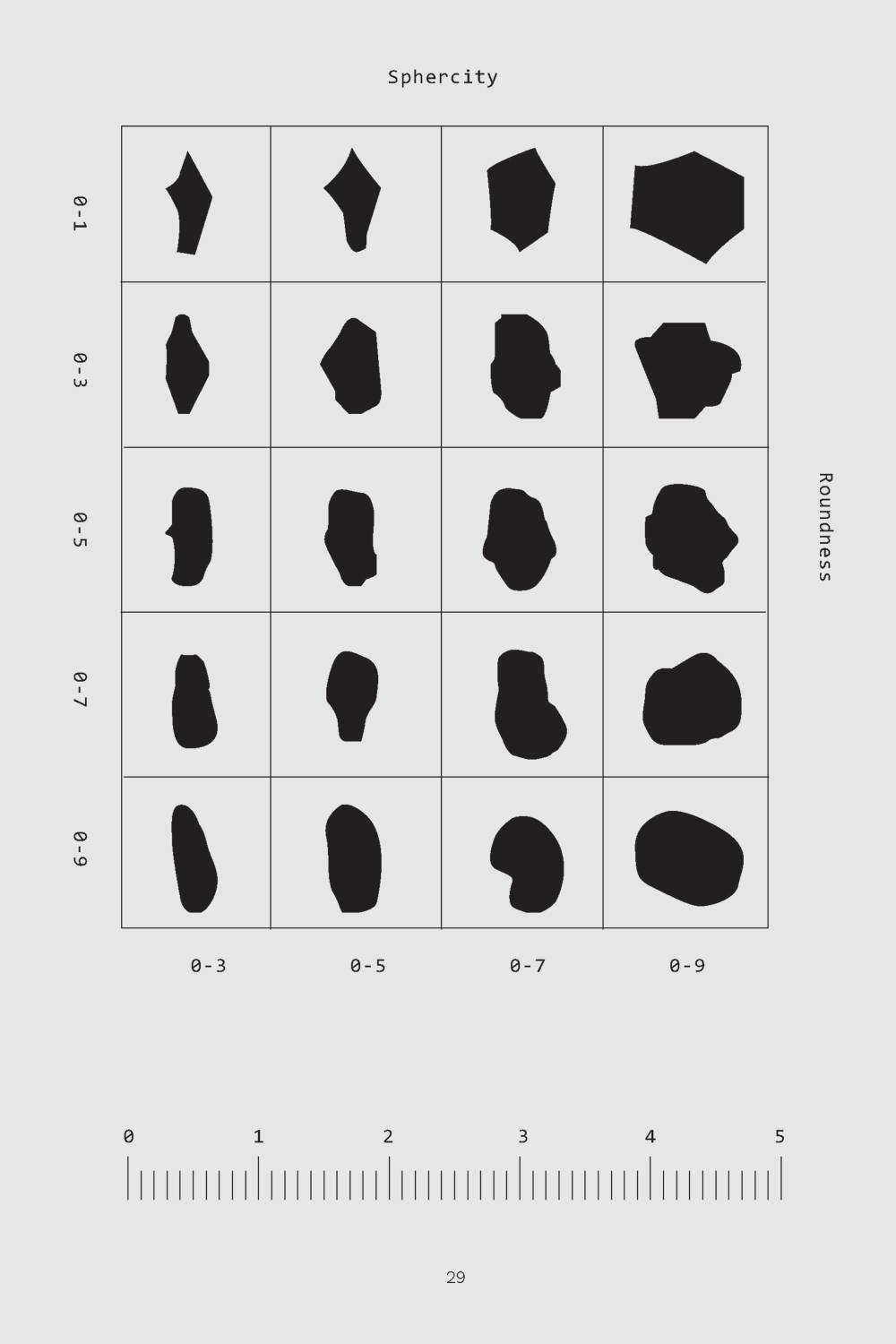

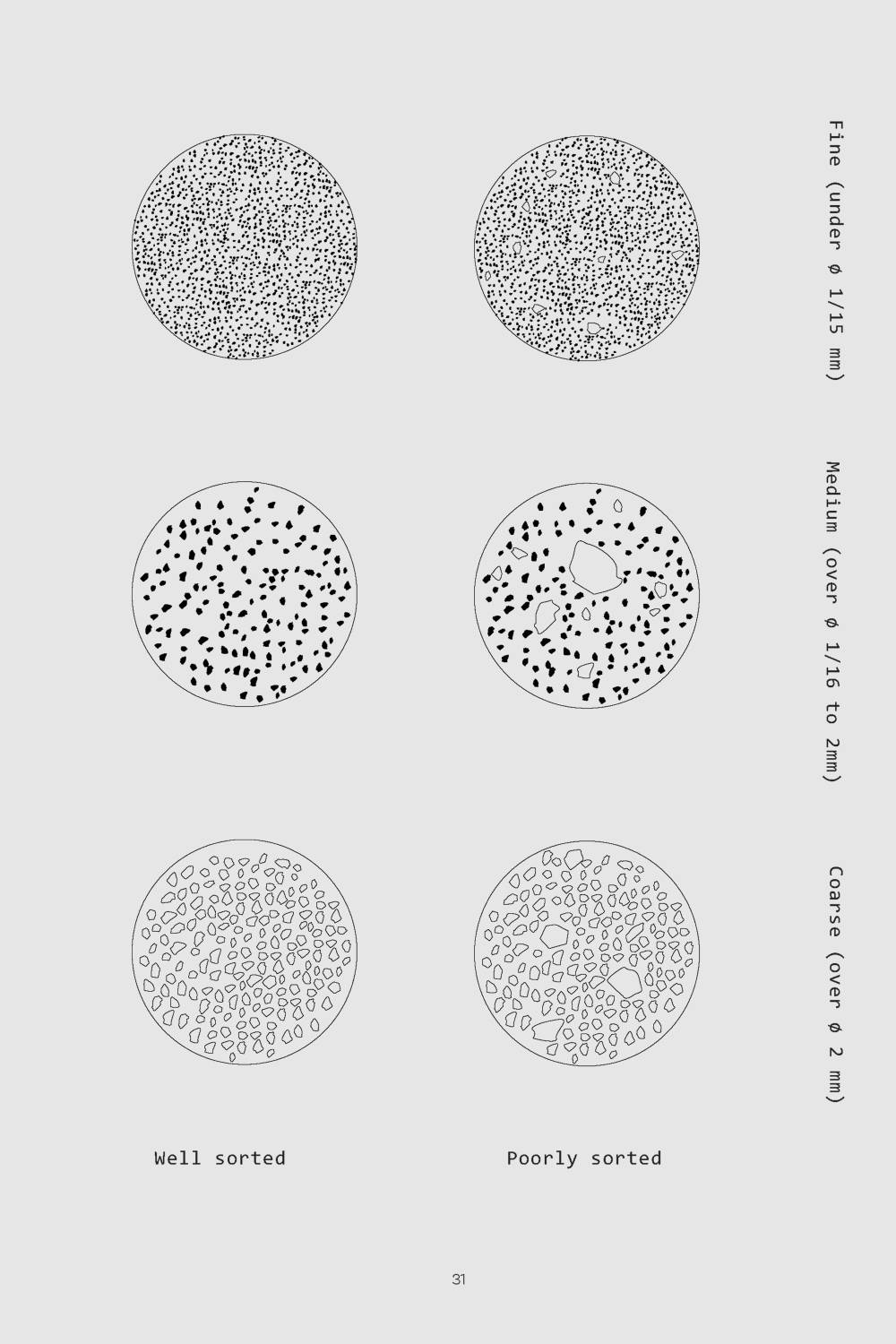

Sand is a naturally occurring, unconsolidated sediment composed mainly of mineral grains with a particle size of 0.063 to 2 millimeters. Sand is thus on average coarser than silt (particle size predominantly 0.002 to 0.063 millimeters) and finer than gravel (grain size predominantly 2 to 63 millimeters). Sand is also one of the non-cohesive soils.

Waste of electrical and electronic equipment WEEE (such as computers, TV-sets, fridges, cell phones and microwaves) is one the fastest growing waste streams in the EU, with some 9 million tonnes generated in 2005, and expected to grow to more than 12 million tonnes by 2020. WEEE Directive

5% of a WEEE is composed of glass in average (excluding other silicates such as silicones, silicon,etc). In the EU waste glass from WEEE is categorised as „special glass“. Most of the WEEE special glass is not recycled. Multi-material streams for glass are very problematic for recycling, partly due to organic leftovers or incompatibility of glass types. When recycled it is remolten — through incineration, which encloses (heavy)metals; it is used as an aggregate for civil works or landfill.